Rough, and sharp nano-punch mechanically damages the pathogen

New technology that can capture and damage micro pathogens in the air just using a filter has been developed. It is expected to be used for filter materials and on surfaces of various antibacterial-related devices in the future as toxic substances are not caused during the antibacterial process and the operation of the additional device is not required.

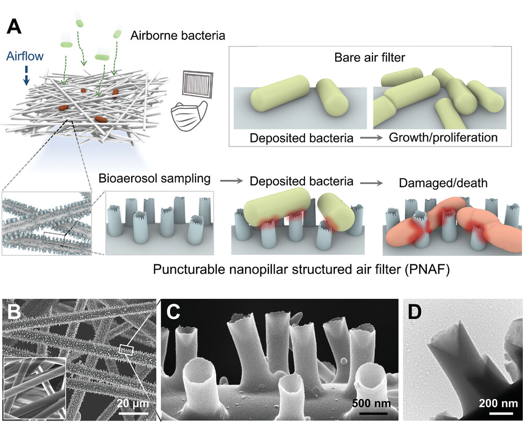

A research team led by Professor Lee Joon-seok of Hanyang University's Department of Chemistry has developed a nanostructured filter that can effectively capture and damage micro pathogens in the air, Hanyang University announced on April 13. This technology uses the effect of mechanically damaging the pathogen that makes contact with the nanostructure without causing chemical stress leading to induced activity decrease and death of micro pathogens in the air that has been captured by the filter membrane.

Air-borne micro pathogens include viruses, bacteria, and fungi, some of which are transmitted to animals or humans, causing various respiratory diseases. Therefore, research on the development of antibacterial filters with high removal efficiency and strong sterilization power is actively underway at home and abroad.

Conventional antibacterial filters are manufactured by including or coating chemical biological agents or antibacterial nanomaterials in filter fibers. Photocatalysts, electrical stimulation, and thermal treatment are sometimes used to sterilize pathogen, which has the disadvantage of being cumbersome because additional energy and external driving devices are required. There are also concerns about reactive oxygen species, residual heat, and inhalation of toxic substances generated during sterilization.

Professor Lee's research team developed a nanostructured filter that physically causes cell damage of micro pathogens on the surface of the air filter without external stimulation and additional devices. Pathogen cells that make contact or get caught on the surface where nanoscale structures smaller than or similar to the size of the pathogen are densely formed get physical damage such as twisting or dents. The damaged pathogen has reduced activity, making it difficult to proliferate further and undergoes death.

In order to take advantage of the mechanical sterilization effect of nanostructures, the researchers formed nanostructure pillars on the surface of the generally smooth air filter membrane using a catalytic droplet-based synthesis method. The mechanical rupture effect was maximized by manufacturing a nano punch structure with rough and sharp edges based on the form of a perforator or punch.

As a result of the study, filters with a wider surface area by nano punch pillars showed a high collection efficiency of more than 98% for suspended bacteria. Compared to the smooth filter membrane, the nano punch structure membrane showed a reduction in the bacterial activity of about 90% and a reduction in the number of proliferating bacteria of about 93%.

Compared to a flat nano-pillar, cells in contact with the nano-punch pillar were observed to be highly stressed at rough edges, making the cell membrane easily deformed. In addition, nanostructures formed based on catalytic droplets are stable in heat, acid, alkali, or organic solvents, and can be used in various atmospheric environments, and there was little concern about nanomaterial release as well.

Professor Lee said, "It can be used as an economical and general-purpose material in the filter market as a material that can actively kill pathogens without external stimuli as well as block the spread of air-borne micro pathogens that cause respiratory diseases."

The study, which was conducted with the support of the Mid-sized Researcher Supporting Project and STEAM Research Projects of the National Research Foundation of Korea, published its paper in “Advanced Functional Materials”, an international journal in the field of materials science on March 29th.

Click to see the paper:

https://onlinelibrary.wiley.com/doi/full/10.1002/adfm.202213650