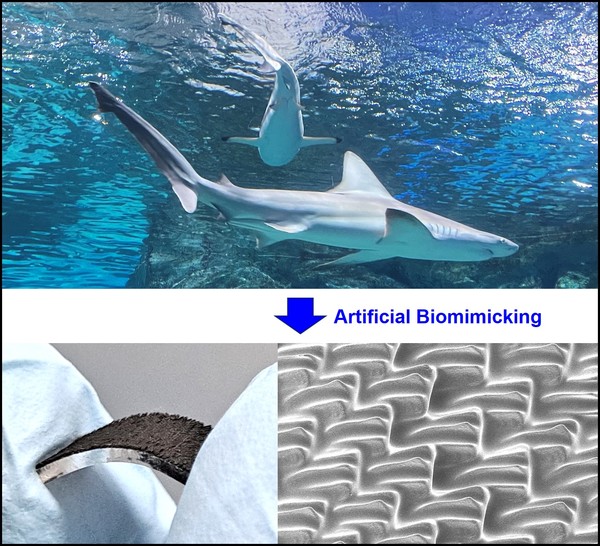

Hanyang University announced on December 11 that Professor Wie Jeong-jae from the Department of Organic and Nano Engineering's research team successfully developed new technology that mimick three-dimensional surface of a shark's skin to implement various unconventional functionalities. Among marine organisms, sharks, with their unique scale structure, can swim rapidly in deep-sea environments. The shark scales feature a series of ridges with home-shaped riblets arranged in an overlapping pattern, reducing drag by allowing water to slip in one direction between the riblets. Additionally, to enable flexible swimming, the skin beneath the scales is soft, while the outer layer is relatively hard, providing resistance against forces penetrating in the thickness direction of the skin, protecting the body from external impacts.

Efforts to mimic the two structural advantages of natural shark scales have been ongoing in previous research. However, conventional methods involved stacking materials to form non-overlapping shapes using printing techniques, or producing surface shapes in a simplistic and non-three-dimensional manner. With these traditional methods, it was challenging to prevent the deformation of riblet shapes when stacking the micro-scale structures in three dimensions. To address this issue, Professor Wie's team successfully achieved three-dimensional stacking by manufacturing micro-scale structures using a composite material of magnetic particles and elastic polymers. They bent each riblet to the extent that the top of one riblet touched the bottom of an adjacent riblet under an external magnetic field. Subsequently, they coated the overlapped riblet with a thin layer of liquid polymer resin, heat-cured it, and removed the magnetic field, maintaining the overlapped shape in the three-dimensional artificial shark scales.

The polymer-based artificial shark scales showcased the prominent function of natural shark scales, which is drag reduction. When water flows in the riblet direction on the hydrophobic surface, micro air bubbles get trapped between the ridges. As water slides over this air layer, a pressure drop occurs. Furthermore, to mimic the layered structure of natural shark scales, the team coated a soft polymer layer with nano-thickness hard ceramic in the riblet direction. This led to a reduction in the friction coefficient for contact scraping in the riblet direction. Additionally, coating the ceramic layer with an even harder metal at nano-thickness enhanced the mechanical strength and resilience against indentation tests.

Furthermore, the research team led by Professor Wie Jung-jae demonstrated the three-dimensional artificial shark scales' electrical conductivity. By implementing a known highly electrically conductive material, a two-dimensional nano-sheet-shaped MXene, with a conductivity of 5,000–10,000 S cm-1, onto the polymer layer, they created artificial shark scales with low electrical resistance, approximately 5.3 Ω. Applying a small voltage to these scales generated high-temperature heat, and due to the hydrophilic nature of MXene, changes in wetting characteristics were observed. Exploiting the multifunctionality of these artificial shark scales in maritime applications could bring economic benefits by reducing fluid resistance, thereby decreasing fuel consumption and extending the operational life of vessels. The potential applications include faster navigation with reduced hydrodynamic drag, minimized friction upon contact with surrounding obstacles, and decreased susceptibility to external impact-induced damage.

This research was conducted with the support of the U.S. Aerospace Research and Development (FA2386-22-1-4086), the National Research Foundation of Korea (NRF-2022R1A2C2002911, NRF-2022R1A2C44001521, NRF-2022R1A2C4002115), and the Ministry of Education (2021R1A6A1A03038858). Additionally, it involved collaborative efforts with the research teams led by Professor Kim San-ha from KAIST's Department of Mechanical Engineering, Professor Lee Seung-goo from Ulsan National Institute of Science and Technology's Department of Chemistry, Professor Kwak Rho-hyun from Hanyang University's Department of Mechanical Engineering, and Professor Han Tae-hee from Hanyang University's Department of Organic and Nano Engineering.

The mentioned paper, titled "Programming Anisotropic Functionality of 3D Microdenticles by Staggered-Overlapped and Multilayered Microarchitectures," was authored by Dr. Jung-Eun Park, a postdoctoral researcher in the Department of Organic and Nano Engineering at Hanyang University as the lead author. The paper has been published in the prestigious international journal "Advanced Materials" with an Impact Factor of 29.4.

Click to read paper:

Programming Anisotropic Functionality of 3D Microdenticles by Staggered‐Overlapped and Multilayered Microarchitectures - Park - Advanced Materials - Wiley Online Library

'한양위키' 키워드 보기

'한양위키' 키워드 보기